Home

Using surface mount components

Many hams have shown that using surface mount components is not as hard as you might think. Some hams might say that their size is a reason that they gave up home brewing. if so, that is a great pity as it really is not that hard, even if you have the degraded sight of a sixty year old who needs two kind of glasses to get through the day.

Obviously, we need help. These little blighters are hard to see and just as hard to grab hold of.

Hobby stores and various other outlets can provide a huge (and illuminated) magnifying glass which is mounted on an articulated arm that will help enormously.

Then we need something that helps keep the component still while we use our other two hands to apply solder and soldering iron. From a tip on the USA based "QRP-L" forum years ago I fashioned a device from a coat hanger. There is a lead weight under that yellow heat shrink sleeving.

and here is a close up photo....

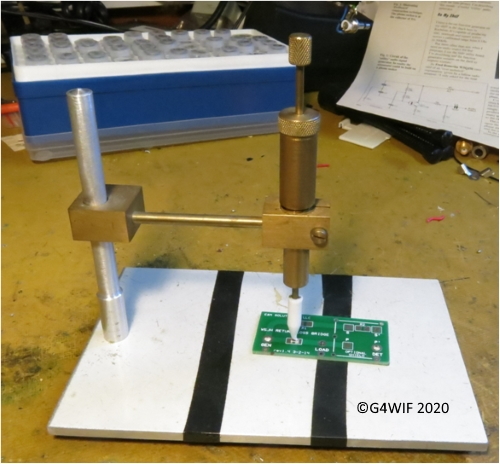

I am fortunate to have as a friend Ted G0ULL who on one birthday gifted me this Rolls Royce of tools with a spring loaded plunger that does a great job. Ted is a very gifted mechanical engineer.

So that takes care of holding the blighters still. How can you build things with them?

Well obviously, there is etching your own printed circuit boards. I can think of no better primer for this than the tutorials of Chuck Adams K7QO. (This link is the 2nd generation of Chuck's videos (the originals were lost). They lack some of the detail of the original but it was good of Chuck to take the time to recreate the method. If you have the ability, I suggest that you download these videos.

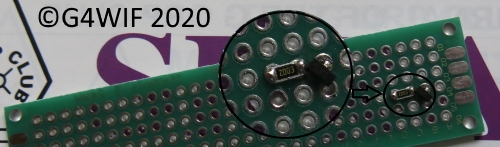

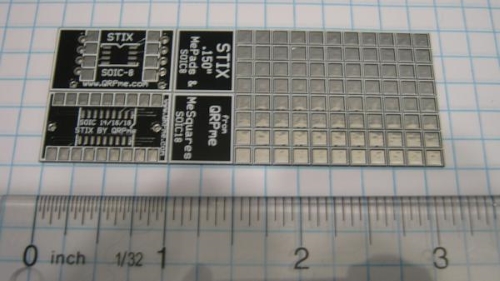

Sometimes though you might want to just build "ad-hoc" and there are many matrix boards available with the right spacing. GQRP Club Sales sells various great products from Rex Harper W1REX.

"QRPme" boards available from GQRP Club in the UK and QRPme in the USA

When I'm making a PCB, and while I have the acid bubbling away, I will usually make a few project boards too. I've covered those here.

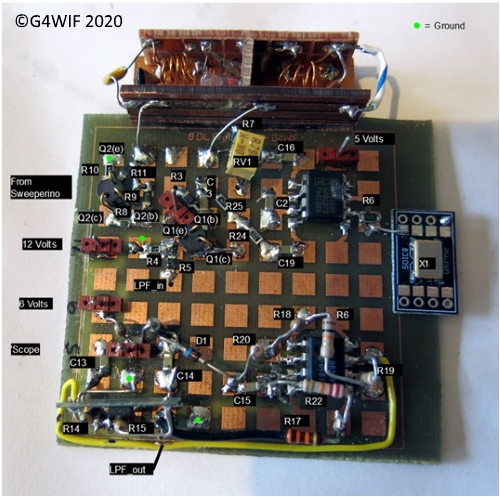

Using the QRPme matrix boards, or one like mine you can quickly make up circuits. The problem might be when coming back to it after a break. Those SMD capacitors have no values to provide a clue. So it is advisable to take a photo and label the parts.

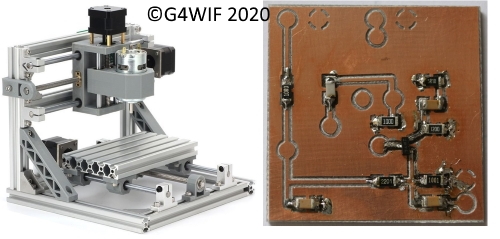

PCB's for surface mount components can also be made using a CNC machine. These things are becoming much more affordable. Below is an example made by Nick G8INE.

"Off the shelf" boards that work with SMD are the very cheap perfboards as shown below.

SOT23 transistors fit diagonally across the holes.

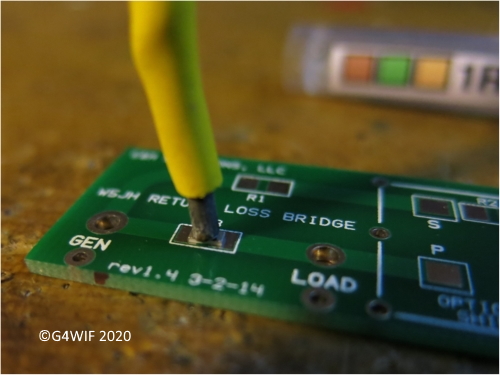

However my favourite "quick and dirty" method is using pad cutters to make small "islands" on a copper PCB sheet. Three holes in a triangular formation are perfect for SOT23 packages.

These cutters are available on EBay or GQRP members can buy them through club sales.

This is a simple multivibrator circuit that I tend to add to many battery powered projects.

It reminds me to turn it off to save on flat batteries.

The two arrows below show where the transistors are located.